HR型双级活塞推料离心机

产品展示

产品中心/PRODUCTS

公司产品分类

联系我们 / Contact us

成都高分离心机有限公司

GK型卧式刮刀卸料离心机

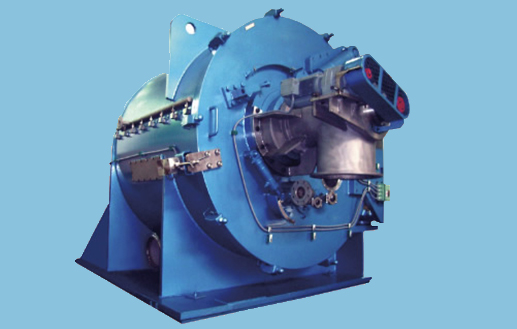

■产品结构原理 结构:GK卧式刮刀卸料离心机主要由刮刀机构、门盖组件、转鼓组件、机座组件、传动系统、液压系统及电气控制系统等部件组成。机座组件为承载部件,主要包括底板、机壳;轴承箱及背板为整体焊接件;转鼓组件为转动部件,主要由转鼓、主轴、轴承及从动皮带轮组成,其中转鼓通过主轴悬臂支承于机座内;机壳前端为门盖,门盖上装有刮刀机构、进料管、洗涤管及卸料斗;液压系统单独外置;主电机上装有液力偶合器,通过三角带与从动皮带轮相联;电气控制系统为单独部件,可安装在操作适宜的位置。 工作原理:主机全速运转后,打开进料阀,被分离的悬浮液通过布料斗进入转鼓内并均匀地分布在过滤介质上。在离心力作用下,液相通过过滤介质和转鼓壁上的小孔甩出转鼓体外,而固相则截留在过滤介质上形成滤渣。当滤渣层达到一定厚度时,关闭进料阀,同时打开洗涤阀对固相物进行洗涤后甩干。最后利用旋转刮刀将滤渣层卸下并经卸料斗送出机外。■ScopeofapplicationStructure:GKhorizontalscraperdischargecentrifugeismainlycomposedofscrapermechanism,doorcovercomponents,drumassembly,framecomponents,transmissionsystem,hydraulicsystemandelectriccontrolsystemandotherparts.Framecomponentforbearingparts,mainlyincludingbackplane,casing;BearingboxandthebackforthewholeproductDrumcomponentsforrotatingparts,mainlybytherotarydrum,mainshaft,bearingandthedrivenpulley,therotarydrumthroughthespindlecantileversupportwithintheframe;Chassisfrontgateofthedoorcover,coverisequippedwithscrapermechanism,feedpipe,washinganddischargehopper;Separateexternalhydraulicsystem;Onthemainmotorisequippedwithhydrauliccoupling,throughtriangleiscombinedwiththedrivenpulley;Electricalcontrolsystemforsingleparts,canbeinstalledinthelocationoftheappropriateoperation.Workingprinciple:thehostafterrunningatfullspeed,openthefeedvalve,isolatedslurrythroughclothbucketintothedrumandevenlydistributedonthefiltermedium.Undertheeffectofcentrifugalforce,theliquidthroughafiltermediumandflungoutdrumdrumwallholesinvitro,whilethesolidphaseinterceptformafiltercakeonthefiltermedium.Whenthefiltercakelayerreachesacertainthickness,feedvalveshut,openatthesametimewashingvalveofthesolidphaseafterthewashingtodry.Therotatingscraperisusedtochangethefilterresiduelayertounloadandclosedtothedischargehoppersent.■产品特点与用途 GK系列离心机是一种卧式宽刮刀卸料、自动控制、连续循环工作过滤离心机。能在全速运转下循环实现进料、分离、洗涤、脱水、卸料、洗网等工序。具有结构新颖、运转平稳、操作方便、适用范围大、自动化程度高、劳动强度低等特点。适合分离含固相物粒度大于0.015mm,浓度范围在25-60%的悬浮液。防爆型可用于易燃易爆的固液分离。适用于化工、化肥、食品、制药等行业。GKseriescentrifugeisakindofhorizontalscraperdischargewide,automaticcontrol,continuousloopfilteringcentrifuge.Canberunatfullspeedloopachievefeeding,separating,washing,dehydration,unloadingandwashthenet.Hastheadvantagesofnovelstructure,stablerunning,easyoperation,largescope,highdegreeofautomation,lowlaborintensity,etc.Suitableforseparationofsolidphaseparticlesizegreaterthan0.015mm,concentrationrangein25-60%ofthesuspension.Explosion-prooftypecanbeusedininflammableandexplosivesolid-liquidseparation.Suitableforchemical,fertilizer,food,pharmaceuticalandotherindustries. ■主要技术参数Themaintechnicalparameters■结构示意图Structurediagram■特别提示 1、技术参数以产品说明书为准。 2、洽询时,请顾客详细赐告物料特性参数及工况条件要求。 3、根据顾客的特殊需要,我们可以采取个性化的设计与制造: (1)材质:物料接触部分材质可为304、316L、2205、2507、904L、TA2等(也可采用衬包结构)。 (2)电机型式:可采用普通型或防爆型电机等。 (3)排液方式:母液与涤液可采取混合排放或分流排放。 (4)GK1600-NB可采用螺旋卸料结构。 (5)可商定其他技术要求。■Specialnote1,thetechnicalparametersoftheproductspecificationshallprevail.2,inquire,pleasecustomerdetailsgiventothematerialcharacteristicparametersandworkingconditionrequirements.3,accordingtothespecialneedsofcustomers,wecantakethepersonalizeddesignandmanufacturing:(1)material:materialcontactpartofthematerialfor304,316l,2205,2507,904l,TA2(alsocanuselinepackagestructure).(2)motortype:canuseordinaryorexplosion-proofmotor,etc.(3)drainageway:motherliquorblendedwithpolyesterliquidcanadoptemissionsorbypassemissions.(4)GK1600-NBcanadoptspiraldischargingstructure.(5)canbeagreedothertechnicalrequirements.

GKH卧式虹吸刮刀卸料离心机

■产品结构原理 本系列离心机主要由刮刀组件、门盖组件。回转体组件、虹吸管组件、机座壳体组件、传动系统及液压系统等组成。 转鼓包括内转鼓(过滤转鼓)和外转鼓(虹吸转鼓)。内转鼓沿圆周开有许多过滤槽,沿轴向均布有许多加强筋,通过相邻两块之间的压块及螺栓与外转鼓联为一体,使内、外转鼓之间形成轴向流体通道。内转鼓内铺设衬网和滤布,滤布两头用O型橡胶条压紧;外转鼓壁上不开孔,外转鼓的转鼓底上对称有斜孔,作为转鼓与虹吸室间的流体通道。整个回转体组件悬臂支承在主轴承上。主轴后端的三角皮带轮,通过三角胶带与主电机上的皮带轮相连。当启动主电机时,就会带动主轴回转体组件运动。轴承箱除支承主轴回转体组件外,其大背板上部通过法兰连接安装有虹吸管组件和反冲管;大背板外圆端面上通过螺栓与机壳相连,门盖上装有刮刀组件。 机器全速运转后,由反冲管向虹吸室内灌水(液体),流体经虹吸室与转鼓的通道压入转鼓,除排去内、外转鼓间空气外,还在过滤介质上形成一液体层,然后开始进料,同时虹吸管旋到某一位置,一定时间后再旋到指定位置,进料结束后虹吸管旋到最低位置。悬浮液进入转鼓后,由于过滤介质上液体层的作用,能使物料均匀分布在过滤介质上,液相在离心力和虹吸抽力的双重作用下快速穿过过滤介质和内转鼓上的过滤孔进入内外转鼓之间的通道,然后经转鼓底上的斜孔进入到虹吸室,由虹吸管排除。而固相则截留在过滤介质上形成滤渣层,经一定时间分离后,旋转刮刀将其刮下,通过斜槽或螺旋卸料机构排除机外。■ScopeofapplicationTheseriesofcentrifugeismainlycomposedofscrapercomponents,doorcovercomponents.Revolvingbodycomponents,components,siphonframeshellcomponents,transmissionsystemandhydraulicsystem,etc.Drumincludingdantiandrumfilter(drum)andouter(siphondrum).Dantiandrumalongthecircumferenceofacircletoopenmanyfiltertank,alongtheaxialuniformhasalotofstiffener,throughthepressurebetweentwoadjacentblocksandboltsandouterdrumetc,formedbetweentheinnerandouterdrumaxialflowchannel.Dantianlaidinsidethedrumlinenetworkandfiltercloth,filterclothwithbothendsOrubberstripcompression;Theouterdrumwalldoesn'topenhole,theouterdrumdrumbottomsymmetricalwithinclinedhole,asfluidpassagebetweenthedrumandsiphonroom.Thewholeofrotorscantileversupportonthemainbearingcomponents.Spindlebackendv-beltpulley,throughtriangletapeisconnectedtoapulleyonthemainmotor.Whentostartthemainmotorwilldrivethespindleaxisymmetricalcomponentmovement.Bearingboxbesidesbearingspindlerevolvingbodycomponent,itsbigupperbackthroughtheflangeconnectioncomponentswithsiphonandrecoiltube;Abackendonthecylindricalthroughboltsareconnectedtothechassis,doorcoverisequippedwithscrapercomponents.Machinerunningatfullspeed,therecoiltubetosiphonindoorwater(liquid),fluidbysiphonchamberandpressureintothedrumdrumtrack,inadditiontotherowbetweentheinnerandouterdrumair,alsoinaliquidlayerisformedonthefiltermedium,andthenbegintofeed,siphonspintoapositionatthesametime,thespinagainafteracertaintimetothedesignatedlocation,afterthefeedsyphonspintothelowestposition.Aftersuspensionintothedrum,becausetheroleoftheliquidlayerfiltermedium,theuniformdistributiononthefiltermedium,canmakethematerialliquidundertheactionofcentrifugalforceandsiphondraughtfastthroughthefiltermediumandconvertedonthedrumfilterholeintothepassagebetweentheinnerandouterdrum,andthenbythedruminclinedholeonthebottomintothesiphonroom,bythesiphonruledout.Whilethesolidphaseinterceptinfiltercakelayerisformedonthefiltermedium,afteracertaintimeseparation,rotatingscraperscraping,throughthechuteorspiraldischarginginstitutionsexcludeclosed.■主要技术参数Themaintechnicalparameters■工作原理workingprinciple■特别提示 1、技术参数以产品说明书为准。 2、洽询时,请顾客详细赐告物料特性参数及工况条件要求。 3、根据顾客的特殊需要,我们可以采取个性化的设计与制造: (1)材质:物料接触部分材质可为304、316L、2205、2507、904L、TA2等(也可采用衬包结构)。 (2)电机型式:可采用普通型或防爆型电机等。 (3)排液方式:母液与涤液可采取混合排放或分流排放。 (4)可采用梭槽卸料结构。 (5)可商定其他技术要求。■Specialnote1,thetechnicalparametersoftheproductspecificationshallprevail.2,inquire,pleasecustomerdetailsgiventothematerialcharacteristicparametersandworkingconditionrequirements.3,accordingtothespecialneedsofcustomers,wecantakethepersonalizeddesignandmanufacturing:(1)material:materialcontactpartofthematerialfor304,316l,2205,2507,904l,TA2(alsocanuselinepackagestructure).(2)motortype:canuseordinaryorexplosion-proofmotor,etc.(3)drainageway:motherliquorblendedwithpolyesterliquidcanadoptemissionsorbypassemissions.(4)canuseshuttletankdischargingstructure.(5)canbeagreedothertechnicalrequirements.

上一页

1

下一页

扫描二维码手机访问

成都高分离心机有限公司

服务热线:

邮箱:

公司地址:

成都市青白江区工业园创新路516号

Copyright © 版权所有·成都高分离心机有限公司 蜀ICP备16031411号 网站建设:中企动力 成都